Your cart is empty.

Best Guide to Knife Steel

(This guide is written by Zvi of zknives.com and edited by Tim Martinez of Knife Depot. For more information and details about blade steels, we highly recommend visiting Zvi's site zknives.com or downloading his knife steel app.)

For an average person not familiar with steel classifications, standards, and properties, it can get very confusing. Oftentimes, the same knife design is offered in more than one alloy. More expensive doesn't necessarily mean better performance, and steels with different names may be the same alloy in the end. The confusion goes on and on.

This guide aims to help you make a more informed choice regarding blade steel. Most of the points apply equally to folding and fixed blade knives, especially smaller fixed blades designed for light/medium cutting. Large, heavy duty knives used for chopping, prying and battonning are not covered in this guide.

Modern knife making uses several thousand alloys, but since non-steel blade materials (Ceramic, Cobalt or Titanium-based alloys) are still rather rare, this guide will focus primarily on steel. Obviously, it is not realistic to cover a few thousand alloys in one article, but you can refer to the knife steel composition chart for alloy composition data and to look up alternate names for alloys mentioned here.

Defining Knife Steel Performance

When discussing knife performance, there are two main factors:

- Ability to retain a sharp edge

- Cutting ability

A distant third factor is ease of sharpening, but it isn't too difficult to put a good edge on any steel using modern sharpening tools. Most sharpening difficulties arise when you need to remove a substantial amount of metal when thinning a bevel or repairing a severely damaged edge. Both are very rare, however. Even on extremely wear-resistant alloys like CPM S125V, it takes less than five minutes to restore a sharp edge.

Many factors determine a folding knife's cutting performance and ability to retain an edge. The number of variables makes choosing the steel for a folder more complicated, but once you understand those variables and their influence on knife performance, it isn't too difficult to pick the optimum fit for your needs and budget.

Instead of simply breaking down alloys into stainless and non-stainless, it is more beneficial to review what makes a knife perform, and allow you to choose by more than stainless vs. carbon steel.

In fact, neither term is technically correct, at least as far as knife steels go. There are only a couple of truly stainless steels used in knives, and all steels are technically carbon steels because steel is a mixture of iron (Fe) and carbon (C), plus optional alloying elements.

Factors When Choosing a Blade Steel

In terms of what to consider when choosing the right blade steel for you, we're going to look at five aspects. You can find more info on each in the sections below, but here's a brief glimpse at each consideration:

- Intended Use - What to cut, push cutting vs. slicing. Has effects on blade and edge geometry, steel choice as well;

- Blade Geometry - Not related to the steel directly, has impact on use, sharpening;

- Edge Geometry - Edge type, angle, coarseness are all important factors, dictated by steel, heat treatment and intended use;

- Corrosion Resistance - Affects steel choice if humidity or aggressive environments are a concern;

- Types of Steels Used in the Blades - Affects all of the above to various degree.

1. Intended Use of the Knife

In my opinion, this is what affects all other factors. It can be phrased differently: using the right tool for the job.

Before buying, you should generally know the primary use of the folder. Obviously, it won't be a single task, but you can optimize for specific cutting tasks or target an all-around folder. Either way, you can do better than picking a random alloy.

That's not to say I've never bought a knife simply because I liked it. I actually have plenty of knives bought without anything specific in mind. Even then, I would still consider potential use and pick an alloy based on that.

Sometimes it's out of your control because you pick a knife you want or get one as a present. Either way, it's still a good idea to know what that steel is good at and how to get the most out of it.

Push cutting vs. slicing is an important aspect of knife use. People typically have a preferred style of cutting, even if they don't pay attention to it. In my observations, most use push cutting initially, but they start sawing vigorously if (or when) the knife dulls. Obviously, it's best to use what is more appropriate for a specific cutting task.

Here's a rather simplified generalization: For push cutting, a fine, high polish, convex edge performs better. In other words, high edge stability is needed. For slicing, a coarse edge will do better. A coarse edge by definition isn't as sharp as the refined 100K grit edge, but for cutting a rope, a coarser edge is more efficient. However, sometimes you may prefer a very sharp, thin edge.

Obviously, at the microscopic level even 100-150K edges are toothy enough to act as micro saw. However, since they are very refined compared to 1000 grit edges, the pressure produced by those fine edges is greater and therefore the edges have a better push cutting performance. On the other hand, bigger teeth on coarse edges work better in saw cutting. The point is steel should be able to perform at high polished edges, and not all alloys are optimized for that.

That brings us back to the steel. While all steels can perform with coarse edges, very fine edges with low angles don't work well on high alloy, high carbide volume alloys. You would need fine-grained, low carbide volume alloys to achieve best results. These include the 1095 and 10xx series in general, M2, W1-W7, 52100, and Hitachi Shirogami/Aogami from the non-stain resistant category. The stain-resistant group includes the 12C27, 13C26, AEB-L, M390 series and more. Unfortunately, those steels don't always score well in the wear-resistance department, at least not when compared to alloys like CPM 10V, CPM S110V, CPM S125V, K294, M4, M2, etc.

If you have to cut a lot of abrasive material like cardboard or rope, then you might want to consider a more wear-resistant alloy. On the other hand, you really wouldn't want to be shaving with a razor sharpened at 700 or even 1000 grit! A razor is an extreme example, but when you need a very sharp edge, you need to have it thin and very fine. Polishing is just a side effect, not a goal.

Finally, before we dive into other performance factors, it's important to note that putting a proper edge on any knife will provide most of its performance, regardless of the alloy. So far, there is no alloy which doesn't dull.

Sooner or later, you must sharpen your knives. A dull knife with high-end steel performs worse than a sharp budget knife. Better steel allows either for a thinner or more durable edge, or both, but it needs to sharpened and properly maintained. It's as simple as that.

Blade Geometry

An important aspect of blade geometry is blade thickness. No matter what steel is used, thicker knives are stronger but cut worse than thinner ones. Heavy duty folders feature thicker blades and sacrifice some cutting ability for strength.

If you are concerned with the strength of your tank folder, you can always opt for a tougher steel, such as CPM 3V or A2. However, a 3/8"-1/4" thickness provides plenty of strength for a folder in any half decent steel.

Edge Geometry

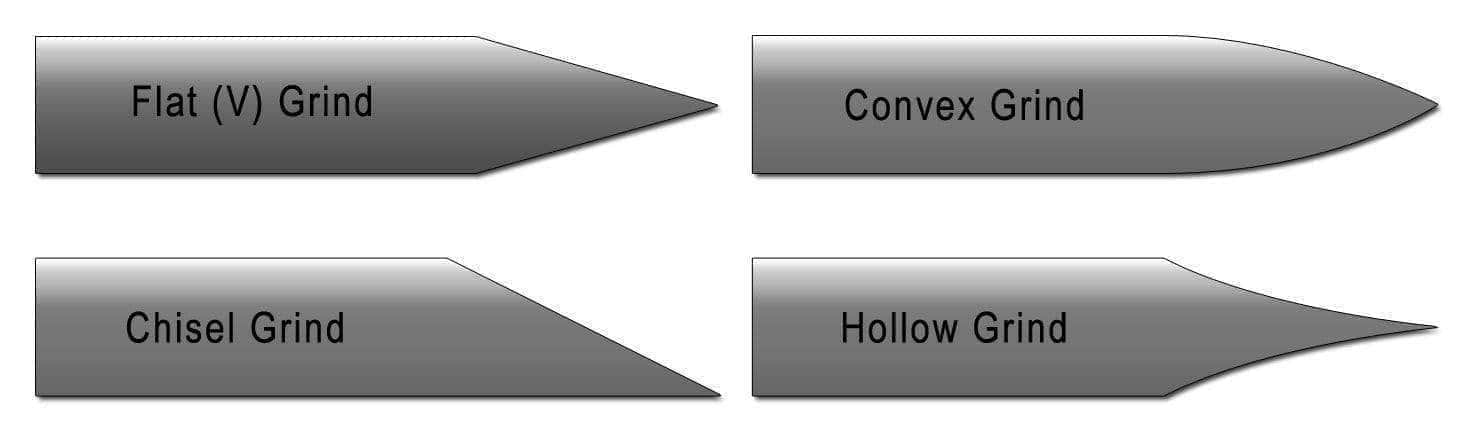

Edge geometry is defined by the shape and angle at which the edge is sharpened.

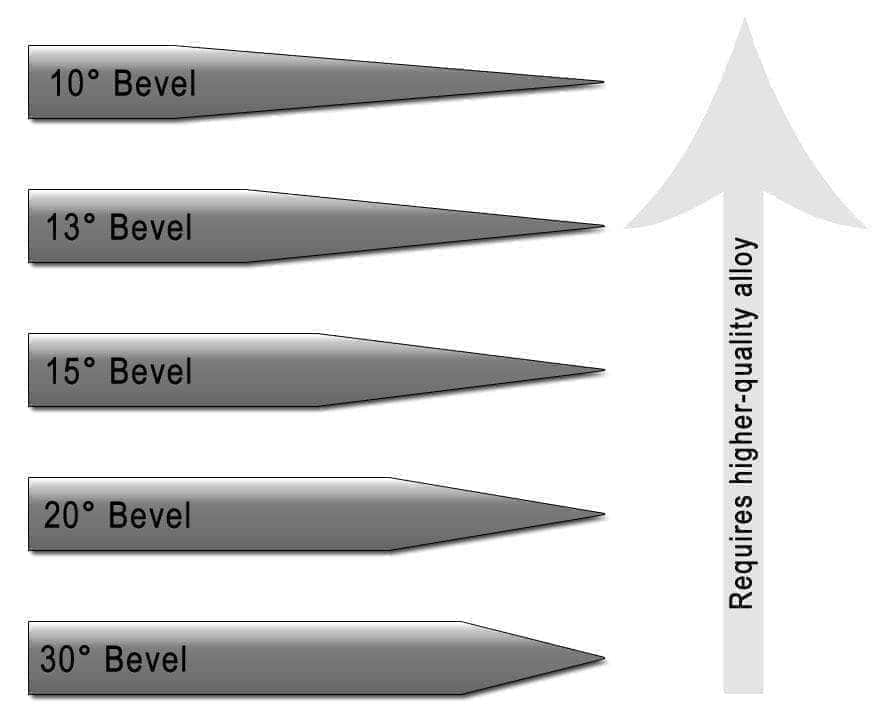

As far as angles go, thin edges cut better while thick edges are stronger and more durable. However, because thicker edges require more force to cut, they don't last proportionally longer than thinner edges. As for the possible edge configurations, there's quite a few to choose from. Diagrams can be viewed on the Knife Edge Types page.

Chisel edge is the sharpest, followed by V grind. You'll need a sharpening system to make V edges because the human hand simply cannot make a straight angle. If you want a V grind, pick fine-grained alloy. In terms of edge angle, not all alloys can support edges below 15° per side, or 30° inclusive. Other than that, intended use should define what type of edge you want on your knife.

Edge geometry is independent from edge finish, but for maximum sharpness you want chisel or V, and then more likely you're looking for a very fine edge as well. Convex edges are sort of a perfect middle ground, providing good balance between edge cutting ability and durability.

To summarize, edges at a 30° angle and above can be supported by all types of alloys discussed here, unless they are underhardened. If you a want thinner edge, then you have to go with fine-grained, low-alloy steels like 1095, W1,W2, O1, Aogami, Shirogami, 52100, AEB-L, 12C27 and similar, plus you need high hardness as well.

For EDC use, a 30° inclusive edge, with a coarse/medium finish 600-1200 grit final finish, any of the alloys will do. If you know the steel is a bit on the softer side, then you can always use a double-bevel edge, which will give you a stronger, more durable edge. It will cut almost the same or even better than single bevel, depending on the thickness of the blade. In other words, behind the edge thickness does play a great role in overall cutting performance, and a low angle secondary bevel improves that aspect, aiding with cutting ability.

Corrosion Resistance

Stain-resistant alloys are more prevalent in folders because they require less maintenance and can take more abuse (from environment and neglect).

The general perception is that stainless steels are more brittle, harder to sharpen and more susceptible to breaking. In reality, none of that is true, or at least represent the true state of matters. If neglected, all stainless steels used in knives will rust, save for H1 and TN15X.

How brittle a knife is depends on heat treatment, geometry, blade thickness and other design aspects. Yes, stain-resistant alloys are not as tough as some of the carbon or tool steels, but that doesn't mean they are brittle on their own. What is more important is the fact that the fine edge is the most susceptible to corrosion than the rest of the blade.

If you do research, you can find quite a few puzzled reports of razor-sharp carbon steel knives getting dull just by sitting in the drawer. That can be avoided if you keep them oiled in the drawer; nevertheless, if you expect humid or aggressive environments for your knife, stain-resistant steel can be a better option.

There are plenty of stainless steels to choose from: 420HC, 425M, 440C, 12C27, 13C26, AUS-6 and AUS-8. Each of these offer decent performance for budget knives. Typically those are around 55-58 HRC, although some of them can be brought up to 60-61 HRC. If you want to squeeze out a bit more from those steels, you can always use a double-bevel edge, with a primary bevel at a 20°-30° inclusive angle and a secondary at about 40°. It'll definitely beat a single bevel 40° inclusive edge.

Mid-range and high-end stainless steels are also abundant; there's CPM154 (which is not 154CM, but a CPM version of it, and Japanese version ATS-34), VG-10, CPM S30V and CPM S35VN. CPM154 and VG-10 can take very fine, polished edges, while S30V and S35VN work best with coarser edges for utility use or high polish edges for kitchen use.

D2, which is a semi-stainless alloy, can produce very good results as well. It works well for utility use in the 58-62 HRC range with a coarse edge, but I've used 64 HRC D2 kitchen knives with 100K polished edges with excellent results.

Then there are high-end alloys like ZDP-189, CPM S90V, CPM S110V, CPM S125V. ZDP-189 can go up to 67-68 HRC. While folders are not quite in that hardness range, even at 63-64 HRC, ZDP-189 performs very well for push cutting. Bear in mind, despite having very high Chromium content - 20%, ZDP-189 is still susceptible to corrosion in humid environments. The reason is simple, 3% Carbon in ZDP-189 ties up a lot of Chromium in carbides, leaving less free Chromium to resist corrosion.

If you prefer coarse edges, or plan on cutting a ton of rope or cardboard, then you might choose CPM S110V, M390 or Elmax.

With the exception of M390 (and its equivalents from Carpenter and Latrobe CTS-204p, Duratech 20CV), alloys mentioned in the last paragraph work best at about 30° inclusive edge. Sharpening those steels (CPM S90V, CPM S110V, CPM S125V) to anything above 1000 grit creates a loss of performance and time. I've done it more than once, alternating between 700-800 grit and 100K edges, and for aggressiveness and durability coarse edges on those steels are very hard to match. At high grits they lose most of the carbides and you are left with not so wear-resistant steel matrix, which does look gleaming sharp, but doesn't have a bite anymore, although it still manages to push cut quite well.

ZDP-189 works well with a high polished edge, but after quite a bit of experimenting, the consensus is that even for kitchen use, 24° inclusive edge is the lower threshold for it, at least when the hardness is in 64-66 HRC range, any lower than that and microchipping will cause excessive dulling. I haven't used ZDP-189 softer than that, but softer steel won't help with thin edges either.

Carbon and tool steels

If corrosion resistance is not a concern, then there are a lot of very good alloys to choose from. There is no official rule separating carbon steels from tool steels (except for the 10xx series, but even those are sometimes referred to as spring or tool steels).

Overall, tool steels is a very large category and has quite a few subgroups. None of those alloys were designed to be used in knives, but some of them happen to work very well. More specifically, high speed and cold working tool steels have quite a few good choices.

Low alloy tool steels are also solid performers in folders. Consider that the Opinels traditionally are made out of that type of alloy. From a price/performance perspective they are hard to beat, combining reasonable toughness and edge stability.

There's a shock-resistant group as well, such as S1, S7, L6, but in folders they don't offer any advantage over other groups. Shock-resistant alloys are best suited for large, heavy-duty blades and swords. Shock resistance on its own doesn't hurt knife performance, but when it comes at the expense of other features more useful in a small knife like a folder, it is undesirable.

From the tool steels category you could pick the best performer for specialized use, or very good all-around use alloys. You can go for better toughness, edge stability, high wear resistance, edge stability or some combination of those. Wear resistance, while being an important factor, doesn't determine edge holding on its own. Toughness and strength are also key factors. If the edge chips or rolls due to a lack of toughness or strength, high wear resistance alone won't do you any good.

Simple, low alloy steels are quite straightforward to heat treat and that makes them more cost effective, plus there's less chance of something going wrong during the HT process. Low alloy steels like 1095, W1 and others are very versatile alloys too. At low/mid range hardness they are suitable for large blades or hard use folders. At maxed out hardness 64-65 HRC, they make very good high performance cutters.

They take an astonishingly sharp edge too. Hitachi Shirogami series, Aogami Super and Aogami 1, 2 are excellent examples. I suppose 1095 wouldn't be the best choice for abrasive material cutting of things like rope or cardboard, unless I kept strictly to push cutting, but that's rather counterproductive. CPM 10V or M4 will provide much better performance for those tasks, and you will end up doing your cutting faster and feel less tired in the end.

More complex (medium and high alloy) steels would include cold working, high speed, ball bearing and other steels. High speed steels are interesting because they are capable of very high hardness combined with reasonable toughness and have enough carbides in them to have solid wear resistance too.

M4 has been a steel of choice in several knives of cutting competition winners. M2 used earlier in Benchmade and Gerber knives was an excellent performer too. That's not to say that a good knife steel has to be a high speed steel though.

Bohler-Uddeholm K390 is a cold work tool steel, and it is one of the best performers out there, especially when cutting abrasive material is involved. D2 is another cold work tool steel, and offers a solid performance with proper heat treatment. 52100 is still popular when refined, high stability edges are desired. CPM 3V is another very good and versatile alloy. Mainly known for its toughness and wear resistance, it is an excellent choice for large knives, but at around 62-63 HRC, it performs very well for small knives and folders. There's CPM 4V and its counterpart Vanadis 4E from Bohler-Uddeholm, which is an even better performer for small knives and capable of 65-66 HRC working hardness.

Another group of steels which some consider to be a direction in future steel evolution is nitrogen steels. Nitrogen has been used in steels for a long time: Busse INFI has ~0.75%, Cronidur - 0.40%, etc. However, if earlier nitrogen percentage in alloy was typically below 0.5%, newer alloys have much higher nitrogen content, Nitrobe 77 - 0.90%, Vanax 35 - 1.90%, and the latest one, Vanax 75 - 4.20%. The last one is a superb performer but rare in folders; however, neither Vanax 35 nor Nitrobe 77 are slouches.

One last word about tool steels in general. Even though a lot of tool steels work well for knives, just because a steel is in a tool steel category doesn't automatically make it a good choice in knives intended for humans. Humans cut very differently compared to machines, plus industrial tools often are nothing like knives in general, even though they are both meant to cut stuff.

Common Knife Steel Types

Every knife owner knows that the blade is what makes or breaks a knife. Before buying any type of knife, you should always know what material the blade is constructed of, as each type has its own advantages and drawbacks.

Though each category often has numerous grades and variations, it's important to have a general knowledge about the blade materials. Below is a short breakdown of the most common types of knife blade materials.

Stainless Steel Blades

The stainless steel blade is one of the most popular for knives because of its durability and resistance to corrosion. Stainless steel is a metal alloy generally made out of at least 11% chromium, iron, nickel, molybdenum and carbon. However, there are many different grades and compositions of stainless steel that vary with the properties used to make the material.

While these blades are favored because of their resistance to rust, they do stain in certain environments and are not usually as sharp as other materials, like carbon or ceramic. The knives that commonly use stainless steel blades include kitchen cutlery, diving knives and pocket knives.

Carbon Steel Blades

Before the popularity of stainless steel, carbon steel was used for most blades. Carbon steel blades are among the sharpest blades available and are much easier to sharpen than stainless steel blades. The lack of chromium in the blades means that it is highly susceptible to rust and corrosion and requires careful cleaning after each use. Carbon steel also gets discolored easily, which is why it is rarely used for high-quality kitchen knives. However, its overall durability and sharpness make it a popular blade material for survival knives, hunting knives and pocket knives.

Titanium Blades

Titanium is a very strong material that's rust-resistant and easy to tell apart from other blade types because of its dark, silver coloring. Titanium blades tend to be softer and not as sharp as other types, so they're sometimes coated with other material. The non-magnetic and durable properties of titanium makes these blades popular with diving knives, pocket knives and even bomb-defusing knives.

Knife Steel Properties

Without going deep into metallurgy, here's a short overview of the key steel properties affecting knife performance.

- Grain Size - Steel is made up of grains, and smaller is better. Decreasing the grain size increases toughness and strength.

- Strength - Ability to resist deformation and rolling. This is mainly controlled by Rockwell hardness.

- Toughness - Ability to resist chipping and/or breakage.

- Wear Resistance - Ability to resist abrasive wear.

- Edge Stability - Ability to hold a fine, acute, polished edge.

Ideally you need the smallest grain size and everything else as high as possible. Unfortunately, in real life, things do not work that way. Increasing strength by raising hardness decreases toughness, and high wear resistance comes with high carbide volume. So you'd need to make some sort of compromise and decide what property is more important, and that is where intended use, edge geometry and the other factors come in.

About Knife Steel Standards And Names

Unfortunately, there is no single rule that can clarify steel naming conventions. The actual picture is very complicated and rather messy. There are dozens of national steel standards, and they keep changing. Some countries have more than one standard. (For example, the US has AISI, ASTM, UNS; Germany has Din and W-Nr; etc.)

Generally speaking, steel standard specification defines alloy compositions, groups them in some way, and then individual steel makers use those standards as a guideline, where they can vary actual steel composition within the specification boundaries. As such, there is no D2 steel per se. D2 is a standard specification for one alloy, from AISI standard. Whoever wants to make an alloy within those specs is free to do so, be it Crucible or Bohler-Uddeholm. They can name their product as D2, or any other name like CPM D2 (Crucible) or K110 (Bohler-Uddeholm).

Because a lot of the steel compositions are similar, standard specifications for many alloys are very close. That allows for cross referencing alloys and making some sense from different names. For example, the same AISI D2 is very similar to Japanese JIS SKD11 or German W-Nr 1.2379 standard specs. However, they don't match 100% either.

Strictly speaking, there is no international steel standards equivalents book, but we can associate alloys by their specifications within some tolerances. Sometimes a single spec from one standard covers several more tight specs from another. For example, AISI W1 has carbon content specified as 0.70%-1.50%, that's more than 100% variation allowed. Several European countries' standards have half a dozen or more individual specifications falling under the W1 standard. And to make matters better, AISI also has its own specifications, such as W107, W108, W109 and so on, which are simply more strict versions on W1.

Aside from standards, there are proprietary alloys, which do not fall under any standard spec. Actually, alloys specifically developed for knives, including CPM S30V, CPM S35V, Aogami series, Shirogami series, VG-10, ZDP-189 and others, do not fall under any national standard. Plus, there are bunch of other very good alloys that were not developed specifically for knives and don't adhere to any standard spec, but work just fine in knives.

As you can see, each steel standard can and does have its own naming conventions, and proprietary alloys have basically whatever name their makers desire. Because of the size of this article, it's not realistic to cover all naming conventions, but a few simple rules for the most popular steel standards(for knife blades at least) are out there.

AISI standard

It was replaced by UNS, but in knife world AISI names are very popular. 1xxx indicates plain carbon steels, where the last two digits specify average % of Carbon, 1095 means plain carbon steel, around 0.95% carbon.

- 5xxx or 51xxx or 52xxx indicates chromium steels

- Ax indicates air hardening, medium alloy tool steel, e.g. A2.

- Fx indicates Carbon/Tungsten tool steel

- Dx indicates cold working tool steel, with Cr between 10%-13%;

- Hx indicates hot working tool steel

- Lx indicates low alloy tool steel

- Sx indicates shock resistant tool steel

- Ox indicates oil hardening tool steel

- Px indicates plastic mould tool steel

- Mx indicates Molybdenum based high speed tool steel

- Tx indicates Tungsten based high speed tool steel

- Wx indicates water hardening tool steel

DIN/EN standards

Cxx or CKxx indicate plain carbon steels, where xx or xxx show percentage of Carbon, with 100 as a multiplier. CK90 would be 0.90% carbon, roughly equivalent of AISI 1095 or 1090.

Steel names preceded with X indicate high alloy steel. The first number after X is always Carbon, with a multiplier of 100. (As an example, X105CrMoV17 has 1.05% carbon, 17% Chromium and unspecified [in name] amount of Molybdenum. You have to dig up the standard spec for precise composition.)

- W-Nr standard

- There are no real rules to decipher content, just numbers. However, groups can be identified by numbers:

- 1.0xxx, 1.1xxx, plain carbon steels

- 1.2xxx - medium alloy tools steels

- 1.3xxx - high speed tool steels

- 1.4xxx - Stainless steels

Summary

Unless you are interested in a specific alloy for one reason or another, you have a wide assortment of steels to choose from. There are no junk steels per se used in today's knife making, unless it's one of those "surgical stainless" steel knives produced by who knows where and how.

There's your base line or entry level alloys, which offer solid performance for mundane EDC uses, which include 420HC, 440C, 8Cr13MoV, 8Cr17, 12C27 and many others. Sharpen them properly and you have a solid performer.

After that it only gets better with high end alloys like ZDP-189, M390, K390, K294, Aogami and Shirogami.

What really matters is if you like the knife, and if you can maintain it and sharpen it properly. The rest is just seeking improvements and perfection.